Optimizing Material y Maquinaria para Apicultura: Essential Equipment for Efficient Beekeeping

Introduction to Material and Machinery for Apiculture Essentials

Effective beekeeping relies heavily on the selection and utilization of high-quality material y maquinaria para apicultura. These essential tools and materials ensure the health of the hive, optimize honey production, and guarantee operational safety. As the apicultural industry advances, embracing durable, food-grade, and innovative equipment is fundamental to achieving sustainable success. In this comprehensive guide, we delve into the core and advanced equipment that define modern apiculture, emphasizing best practices, innovative trends, and critical considerations for selecting the right machinery and materials for your apiary.

Core Equipment for Apiary Success and Privacy Configurations

Essential materials for hive maintenance and biosecurity

The foundation of a productive and healthy apiary begins with the right materials for hive construction and maintenance. High-quality, immunized wooden components, such as the alzas apícolas (supers) and marcos armados (frames), are crucial to withstand environmental pressures and prevent disease. Moreover, biosecurity measures, including secure hive covers and entrance reducers, prevent intruders and protect against pests like Varroa mites. A critical aspect often overlooked is the choice of food-grade materials for storage and handling, such as stainless steel soporte antigoteo inoxidable, which minimizes contamination risks and facilitates cleaning.

Privacy settings for digital and physical security of apiary data

In today’s digital era, apiary management extends beyond physical tools to encompass data privacy. Proper digital privacy settings safeguard sensitive information about hive locations, production data, and proprietary management practices. Physical security also warrants attention—fencing, surveillance cameras, and limited access protocols help prevent theft or vandalism. Combining robust physical security with privacy-conscious digital systems ensures comprehensive protection, reinforcing confidence in your apiary operations.

Implementing support antigoteo inoxidable for spill prevention

One of the most practical advancements in apiary equipment is the support antigoteo inoxidable—a stainless steel, anti-drip support system designed to prevent honey spills during extraction and transport. This feature not only maintains cleanliness but also improves safety by reducing sticky hazards and preserving the integrity of stored honey. Proper installation and maintenance of these supports extend equipment lifespan and streamline workflow, especially vital in high-volume operations.

Advanced Machinery and Accessories for Large-Scale Beekeeping

Utilizing 300kg pintura alimentaría drums for honey and wax

For large-scale apiaries, efficient storage solutions are essential. Heavy-duty bidones de 300kg pintura alimentaría (food-grade drums) serve as optimal containers for honey, beeswax, and other raw materials. Their robust construction ensures chemical inertness, avoiding contamination, and facilitates bulk handling. Proper sealing and labeling are fundamental to comply with food safety standards and inventory management. Moreover, these drums can be integrated into automated transfer systems, reducing manual handling and increasing operational efficiency.

Specialized cubo metálico de miel for honey storage and handling

The cubo metálico para miel (metal honey bucket) is another vital piece of equipment. With a 25kg capacity, this durable, food-grade container simplifies honey collection and transport from hive to processing facility. Its sturdy construction withstands frequent use and cleaning, and its design ensures minimal honey loss during handling. Implementing protocols for cleaning and sanitation of these buckets guarantees product quality and prevents cross-contamination.

Sieves and cedazo para escurrir sello to optimize extraction processes

Efficient honey extraction depends on proper filtration and separation techniques. The cedazo para escurrir sello (sieve for sealing in drums) plays a crucial role in filtering impurities and ensuring clarity. This equipment allows beekeepers to remove wax, debris, and other contaminants, resulting in premium-quality honey. Regular maintenance and timely replacement of sieves prevent clogging issues, ultimately improving throughput and product purity.

Best Practices for Handling and Maintaining Apiary Equipment

Cleaning and sanitizing stainless steel support antigoteo inoxidable

Proper maintenance of stainless steel support antigoteo inoxidable prolongs its usability and ensures food safety. Cleaning after each use with warm water and food-safe detergents prevents residue buildup. Periodic sterilization using approved sanitizers mitigates microbial risks. Quality stainless steel is resistant to corrosion, but inspecting for surface damage and deformations maintains equipment integrity.

Proper storage and transport of bidones de 300kg and 75kg

To preserve the contents and prolong equipment life, bidones should be stored in covered, climate-controlled environments. During transport, secure fastening minimizes movement and potential spills. Regular inspection for leaks, corrosion, or damage is crucial, especially in demanding field conditions. Implementing standardized handling procedures ensures safety and maintains product quality.

Ensuring longevity and safety of material y maquinaria para apicultura investments

Investing in durable, food-grade, and ergonomically designed equipment yields long-term benefits. Regular training for staff on maintenance and proper handling reduces wear and prevents accidents. Documenting usage logs and maintenance schedules enhances accountability. Adopting these best practices maximizes return on investment and sustains hive productivity.

Future Trends and Innovations in Material and Machinery for Apiculture

Emerging sustainable and eco-friendly equipment designs

The industry is moving towards eco-conscious designs—biodegradable hive components, energy-efficient fans, and solar-powered hive monitoring systems. Materials like recycled plastics and biodegradable plastics reduce environmental impact. These innovations not only promote sustainability but also appeal to eco-aware consumers and regulators.

Integration of automation and smart systems in apiary machinery

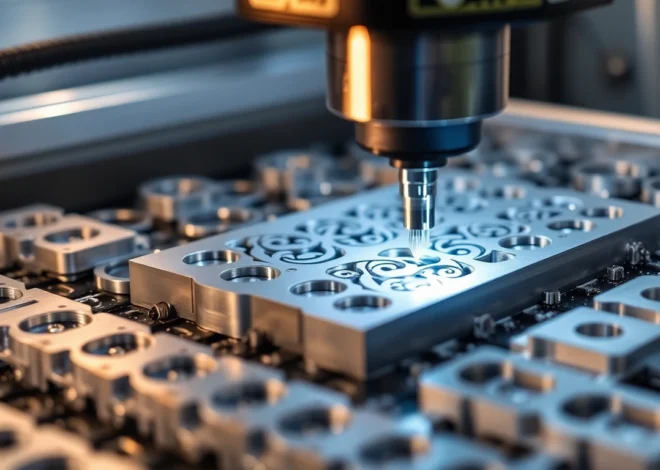

Smart technology integration, such as automated hive monitors, climate control systems, and robotic extraction equipment, revolutionizes apiculture. These tools optimize hive conditions, detect issues early, and streamline honey extraction, reducing labor costs and enhancing precision. Implementing IoT (Internet of Things) devices enables real-time data collection, supporting data-driven decision-making.

Balancing cost, efficiency, and compliance with food safety standards

While cutting-edge equipment offers significant advantages, cost considerations remain paramount. Selecting machinery that complies with food safety standards ensures market acceptance and legal compliance. Balancing initial investments with long-term gains involves strategic planning, vendor evaluation, and pilot testing. Continuous improvement cycles and staying abreast of regulatory developments underpin sustainable growth.